Fascination About Custom Plastic Extrusions

Wiki Article

Not known Incorrect Statements About Plastic Extrusion Manufacturers

Table of ContentsSee This Report on Custom Extrusion ManufacturerThe 4-Minute Rule for Custom Plastic ExtrusionsSome Known Incorrect Statements About Plastic Extrusion Companies Some Known Facts About Custom Plastic Profiles.The 5-Minute Rule for Custom Plastic Profiles

At Vip, we have decades of experience production hundreds of unique custom-made plastic extrusions in nearly every form, dimension, and color you can envision - https://www.netvibes.com/subscribe.php?preconfig=2314d8dc-5b2d-11ed-8360-a0369fec9dc8&preconfigtype=module. Our specialized lies in making plastic accounts particularly for a particular application. You inform us what you need and also we will make it, satisfying the highest possible high quality criteria.From pre-prototype to post-production, ACE has the ability and also innovation to do it all. We serve big and small companies in sectors varying from vehicle to medical, with tough material requirements to limited resistances in America, Canada, Mexico, and Europe. No matter where you are or what industry you stand for, you can depend on ACE for individualized service and also consumer fulfillment.

That indicates quick quotation service or product suggestion is just a call away - http://go.bubbl.us/d10adb/0b88?/Keller-Plastics. Your questions are always responded to immediately by our experienced solution team, and also you obtain the aid you require with no hold-ups or complication. Thank you for visiting our website, we are right here to assist you. Please contact your ACE sales rep at 414-332-8133 or email to discuss product or services.

Custom Plastic Extrusions Can Be Fun For Everyone

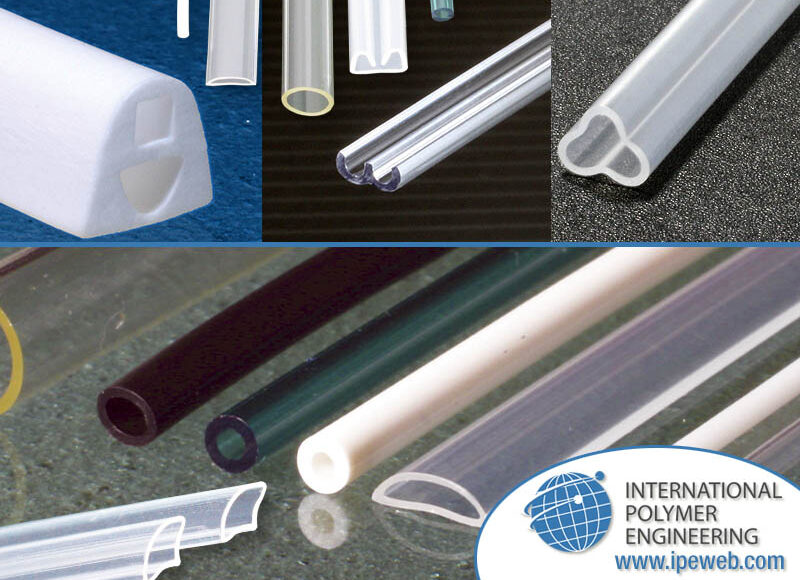

With over 100 combined years of experience in plastic extrusion, GSH Industries is a leading B2B vendor of custom-made plastic extrusions, tubes, and also plastic profiles in North Ohio. Our developers and engineers can assist you in selecting the ideal products for your product line - https://slashdot.org/submission/16827503/keller-plastics. We have a vast selection of plastic materials and also can match any custom shades to your customer's specs - extrusion of plastics.It is just one of the most preferred means plastic parts are currently created as a result of its convenience. Custom-made extrusions can be created into complex shapes of differing thicknesses, toughness, dimensions, colors, as well as also textures, and also are reasonably easy to deal with. The extrusions can additionally be created with performance improving features such as fire resistance, improved durability, enhanced stamina, anti-friction or anti-static residential properties, and a lot more.

It can additionally possibly result in longer cooling time with will certainly raise your total production time as well as expenses. Sharp edges and also notches develop powerlessness in the account where breaking or failure can happen considering that they minimize the effect resistance of the account by developing a high stress and anxiety concentration. Ideally, when developing your profile extrusion sharp corners ought to be avoided entirely rather go for rounded corners.

4 Easy Facts About Plastic Extrusion Profiles Shown

015" (0. 381 mm). Ideally the radius needs to be equal to the wall surface thickness of the extrusion too. This adds to smoother product flow throughout extrusion and much less anxiety on the account's corners. Hollow profiles and also other details include rather a bit of intricacy to an extruded shape. They need additional adjustments to the die to make sure correct material circulation, can trigger unequal air conditioning, as well as can create areas of weak point that could result in failing.If your part should have hollows, a hollow within one more hollow is never an excellent idea. It will be dislodged of form prior to the extrusion strengthens - https://businesslistingplus.com/profile/k3ll3rpl4st8/. If your extrusion needs features such as legs, grooves, snap-ins, or other items inside of the extrusion it is best to develop a conveniently obtainable opening into the extrusion to ensure that you can better integrate those attributes.

6 Easy Facts About Extruded Plastic Profiles Explained

Understanding some consumers may be unknown with our plastic account extrusion abilities, we have actually put together a listing of inquiries we are regularly asked. Durometer is a dimension of the material's hardness and is measured with a gadget which is pressed against the profile's surface area, resulting in a dial guage analysis.

Usual scales are Coast A for versatile materials and Coast D for rigid compounds. Double durometer, or co-extrusion, is the blend of 2 or even more products of differing physical properties right into a single extruded piece. An example would certainly be a rigid part with versatile fingers that could be utilized as a gasket or Recommended Site pillow.

Nevertheless, depending upon the component complexity as well as basic materials, one might estimate the costs starting at less than $1,000. This is a prime example of "all of it depends." As a result of differing set-up expenses and also run efficiencies, we attempt to restrict the minimum manufacturing quantity to 1,000 lineal feet. This amount may differ depending on the forecasted costs, which are considerably greater for shorter run sizes.

Our Custom Plastic Extrusion Manufacturers Ideas

Initially, what causes the line. If you take a close check out an attracting for a plastic profile with an intersection leg, you will certainly see there is more mass in the area of the junction. Given that thermoplastic products reduce some during the cooling procedure, the intersection of 2 legs cools at a slower price than the remainder of the profile, causing it to diminish even more due to the mass of the profile.

A device designer would generally divide the circulation of the 2 legs within the die, and also allow them to come back together as the extrudate is being pressed to the front of the extrusion die. This can sometimes produce a weld line where both thaw streams are restored with each other so mindful tuning of the extrusion tooling is vital to decrease this line.

Report this wiki page